Understanding Differential Adjustment Manuals (PDF)

Differential adjustment manuals in PDF format provide detailed instructions for maintaining optimal vehicle performance. These guides offer searchable text, aiding in quick access to crucial information regarding gear settings and troubleshooting.

What is a Differential and Why Adjustment Matters

The differential is a vital component of a vehicle’s drivetrain, allowing wheels on the same axle to rotate at different speeds – essential during turns. Proper adjustment ensures smooth operation, prevents excessive wear, and maximizes fuel efficiency. Ignoring differential maintenance can lead to noisy operation, binding, or even complete failure, impacting vehicle safety and performance.

PDF manuals are crucial because they detail specific procedures for various differential types. They outline backlash settings, pinion depth, and bearing preload – all critical parameters. Accurate adjustment, guided by these manuals, minimizes friction, distributes power effectively, and extends the lifespan of the differential assembly. Without precise settings, handling and stability are compromised.

The Importance of a PDF Manual for Differential Adjustment

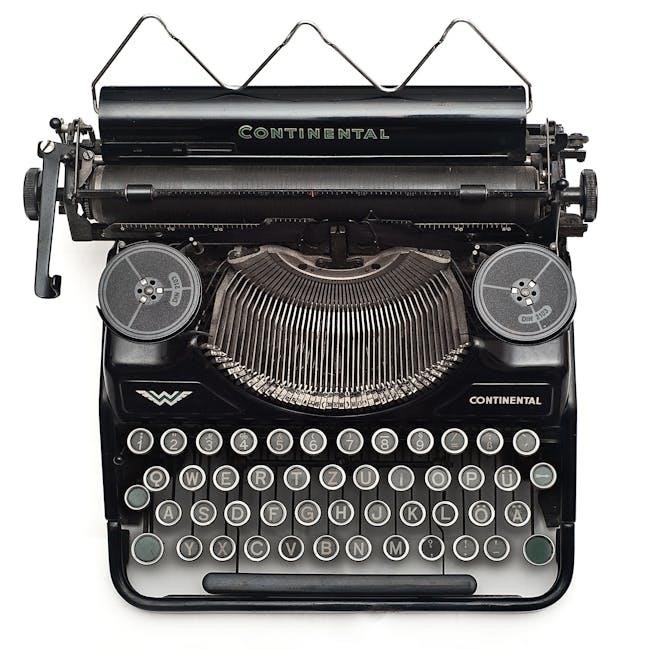

A PDF manual provides a comprehensive, readily accessible resource for differential work. Searchable text and indexing allow technicians to quickly locate specific procedures and specifications, saving valuable time. Zoom and annotation tools facilitate detailed study and note-taking during the adjustment process.

Unlike paper manuals, PDFs are durable, portable, and easily backed up. They often include detailed diagrams and illustrations, clarifying complex steps. Printable formats offer convenience for shop floor use, while accessibility features cater to diverse learning styles. Utilizing a PDF manual ensures accurate, consistent adjustments, minimizing errors and maximizing the longevity of the differential.

Locating Differential Adjustment Manuals Online

Online resources, including dedicated websites and forums, offer a vast library of differential adjustment manuals in PDF format for convenient download.

Keyword Strategies for Finding Specific Manuals

Effective searching relies on precise keywords. Combine “differential adjustment” with the vehicle’s make, model, and year. Include terms like “repair manual,” “service manual,” or specifically “PDF” to refine results. For example, “Toyota Hilux 2018 differential adjustment PDF” yields targeted outcomes.

Experiment with variations; try “gearbox adjustment,” “limited-slip differential repair,” or the specific differential type (e.g., “Torsen differential manual”). Utilizing part numbers, if known, significantly narrows the search. Boolean operators like “AND” and “OR” can further refine queries. Remember to check multiple sources, as manual availability varies across platforms. ManualLib.com and similar sites are excellent starting points.

Popular Websites for Downloading Differential Manuals

Several online platforms host differential adjustment manuals. ManualLib.com boasts a vast library with over a million free PDFs from 10,000+ brands, offering a convenient search function. Manufacturer websites, like Toyota or Ford, often provide downloadable service manuals, though registration may be required.

Dedicated automotive repair sites and forums frequently share links to manuals. Online marketplaces, such as eBay, sell both physical and digital copies. Be cautious of unofficial sources; verify the manual’s authenticity and compatibility with your specific differential model. Always scan downloaded files for viruses before opening them. Remember to respect copyright restrictions when downloading and distributing manuals.

Free vs. Paid Manuals: What to Expect

Free differential adjustment manuals, often found on sites like ManualLib, can be valuable but may lack detail or be incomplete. They might cover a range of models, requiring careful filtering for your specific differential. Paid manuals, sourced directly from manufacturers or reputable repair information providers, generally offer comprehensive, model-specific instructions.

Expect higher quality diagrams, detailed torque specifications, and troubleshooting guides with paid options. These often include searchable text and indexing for efficient information retrieval. While free manuals are a good starting point, investing in a paid manual ensures accuracy and minimizes the risk of errors during adjustment procedures, potentially saving costly repairs.

Decoding a Differential Adjustment Manual (PDF)

PDF manuals utilize searchable text and indexing for easy navigation. Understanding sections, safety warnings, and required tools is crucial for successful differential adjustments.

Understanding Manual Sections and Organization

Differential adjustment manuals typically begin with safety precautions and a component overview. Following this, you’ll find detailed sections dedicated to specific differential types – open, limited-slip, Torsen, and electronic. Each section outlines unique adjustment procedures, often including torque specifications and visual diagrams.

A crucial part is the tools list, ensuring you have everything needed before starting. Manuals are often organized logically, progressing from pre-adjustment inspections to backlash measurement, pinion depth, and bearing preload adjustments. Look for troubleshooting guides addressing common issues like noise, binding, or leakage. The presence of an index and searchable text significantly enhances usability, allowing quick access to specific information within the PDF document.

Safety Precautions and Warnings

Differential adjustment involves working with heavy components and potentially hazardous tools. PDF manuals consistently emphasize the importance of wearing safety glasses and gloves throughout the process. Disconnecting the vehicle’s battery is a primary precaution to prevent accidental electrical shock or damage.

Always support the vehicle securely with jack stands – never rely solely on a jack. Manuals warn against working under a vehicle without proper support; Be mindful of hot surfaces, especially after driving. Torque specifications must be strictly adhered to, as over or under-tightening can lead to component failure. Finally, manuals often caution against modifying components or procedures without expert knowledge.

Tools Required for Differential Adjustment

Differential adjustment, as detailed in PDF manuals, necessitates a specific toolkit. Essential items include a torque wrench, capable of accurately measuring tightening force, and a set of sockets and wrenches to fit differential components. Dial indicators are crucial for precise backlash and pinion depth measurements.

Specialized tools like a pinion nut holding tool and bearing preload tools are often required. A pry bar or similar lever assists in component separation. Manuals frequently recommend a magnetic base for securely mounting dial indicators. Furthermore, a fluid drain pan and appropriate gear oil are necessary for completing the process. Proper hand tools and safety equipment are paramount.

Types of Differentials and Adjustment Procedures

PDF manuals detail adjustments for open, limited-slip (LSD), Torsen, and electronic differentials, each requiring unique procedures based on their internal mechanisms and design.

Open Differential Adjustment

Open differential adjustment, as detailed in PDF manuals, primarily focuses on setting the correct backlash and pinion depth. These manuals emphasize the importance of precise measurements using dial indicators to ensure smooth operation and prevent premature wear. The process typically involves loosening the pinion nut, adjusting the pinion depth shims, and then tightening the nut to the specified torque.

Backlash adjustment involves checking the gear mesh by rotating the pinion and measuring the rotational play. PDF guides illustrate how to use shims to eliminate excessive backlash, which can cause noise and impact gear life. Proper adjustment minimizes friction and maximizes power transfer, contributing to overall vehicle efficiency. Detailed diagrams within the manuals aid in visualizing the component locations and adjustment points.

Limited-Slip Differential Adjustment

Limited-slip differential adjustment, as outlined in PDF manuals, is more complex than open differentials due to the inclusion of clutches or gears that manage torque distribution. These manuals detail procedures for preloading the clutches or adjusting the conical gears to achieve the desired slip rate. Accurate torque wrench application is crucial, as over-tightening can cause binding, while insufficient preload reduces effectiveness.

PDF guides often include specific instructions for different limited-slip designs, such as clutch-type, Torsen, or viscous couplings. They emphasize the importance of verifying proper function after adjustment, often through road tests or specialized equipment. Correct adjustment ensures optimal traction during cornering and off-road conditions, enhancing vehicle stability and performance. Diagrams clearly illustrate the internal components and adjustment mechanisms.

Torsen Differential Adjustment

Torsen differentials, detailed in PDF adjustment manuals, require a unique approach compared to other types. These differentials rely on worm and spur gears to distribute torque, and adjustment primarily focuses on maintaining proper gear mesh and preload. PDF guides emphasize that Torsen differentials are largely self-adjusting, but disassembly for servicing necessitates precise reassembly.

Manuals highlight the importance of using the correct lubricants and torque specifications during reassembly to ensure smooth operation and prevent premature wear. Checking for proper backlash and ensuring the gears rotate freely are critical steps. Unlike clutch-type LSDs, Torsen differentials don’t typically have adjustable preload; maintenance centers on cleanliness and correct component installation as described in the PDF.

Electronic Differential Adjustment

Electronic differentials, covered extensively in PDF adjustment manuals, present a different set of challenges. These systems utilize sensors, actuators, and a control module to dynamically adjust torque distribution. PDF guides emphasize that adjustment often involves diagnostic scanning and software recalibration rather than physical shimming or gear adjustments.

Manuals detail the use of specialized scan tools to monitor differential operation, check sensor readings, and perform actuator tests. Calibration procedures, outlined in the PDF, are crucial for ensuring the system functions correctly. Troubleshooting often involves identifying fault codes and addressing underlying sensor or actuator issues. Physical inspection of wiring and connectors is also vital, as described in the PDF documentation.

Step-by-Step Differential Adjustment Guide (General)

PDF manuals guide users through inspection, backlash measurement, pinion depth, and bearing preload adjustments, ensuring precise differential operation and longevity.

Pre-Adjustment Inspection

Before commencing any differential adjustment, a thorough inspection, as detailed in your PDF manual, is paramount. Begin by visually examining the differential housing for any signs of damage, such as cracks or leaks. Carefully inspect the pinion seal and bearings for wear or play.

Rotate the driveshaft and pinpoint any unusual noises or binding, indicating potential internal issues. Check the gear oil for metal shavings, a clear sign of gear damage. Verify the proper fluid level and condition.

Confirm all mounting bolts are securely tightened. A PDF manual will often include torque specifications. Finally, assess the condition of the ring and pinion gears, looking for chipped, worn, or broken teeth. This initial assessment, guided by the manual, prevents further damage during adjustment.

Backlash Measurement and Adjustment

Backlash, the play between gears, is critical for smooth operation and is meticulously addressed in your differential adjustment PDF manual. Measurement typically involves using a dial indicator to quantify rotational movement. The manual will specify acceptable backlash ranges for your specific differential type.

Adjustment is commonly achieved by shimming the pinion depth or adjusting preload on the pinion bearing. Carefully follow the manual’s instructions, as incorrect adjustment can lead to noise, wear, or failure.

Tightening or loosening the pinion nut alters the backlash. Re-measure after each adjustment, iteratively approaching the specified value. A PDF manual often includes detailed diagrams illustrating the adjustment process.

Pinion Depth Adjustment

Pinion depth adjustment, detailed within your differential adjustment PDF manual, directly impacts gear contact and overall differential performance. This process involves altering the pinion gear’s position relative to the ring gear. The manual will guide you through identifying the correct depth using methods like gear marking compound analysis.

Shims, placed behind the pinion bearing, are used to modify the depth. Adding shims increases depth, while removing them decreases it. The PDF manual will specify the correct shim sizes and installation procedures.

Proper depth ensures optimal gear engagement, minimizing noise and maximizing efficiency. Always refer to the manual’s torque specifications when tightening the pinion nut.

Bearing Preload Adjustment

Bearing preload adjustment, as outlined in your differential adjustment PDF manual, is critical for bearing longevity and smooth operation. Insufficient preload causes excessive play and noise, while excessive preload leads to overheating and premature failure. The manual details specific procedures for both pinion and carrier bearings.

Typically, preload is adjusted by tightening the bearing caps to a specified torque, or by using shims to control bearing clearance. Your PDF manual will provide precise torque values and shim selection guidance.

Using a dial indicator to measure bearing play is often recommended. Always consult the manual for the correct method and acceptable preload range.

Troubleshooting Common Differential Issues

Differential PDF manuals assist in diagnosing noises, binding, or leakage. They provide step-by-step guidance for identifying root causes and implementing effective repair solutions.

Noisy Differential

A noisy differential often signals internal wear or improper adjustment, and a comprehensive differential adjustment PDF manual is invaluable for diagnosis. These manuals detail potential causes, ranging from worn gears and bearings to insufficient lubrication. They guide technicians through identifying the specific type of noise – whining, clunking, or growling – and correlating it with potential issues.

The manuals provide procedures for inspecting gear patterns, checking backlash, and assessing bearing preload. They emphasize the importance of using appropriate tools, like dial indicators, for precise measurements. Furthermore, they often include exploded diagrams illustrating component locations and relationships, aiding in accurate identification of worn parts. Correcting a noisy differential requires careful adherence to the manual’s instructions to ensure proper gear mesh and minimize further damage.

Differential Binding

Differential binding, where one wheel resists rotation, indicates a severe internal problem, and a detailed differential adjustment PDF manual is essential for resolving it. These manuals outline systematic diagnostic steps, starting with checking for physical obstructions and progressing to internal component inspection. They emphasize the importance of identifying the root cause – potentially worn gears, damaged clutches in limited-slip differentials, or incorrect preload.

The manuals provide precise instructions for disassembling the differential, inspecting each component for wear or damage, and reassembling it with correct clearances and torque specifications. They often include troubleshooting flowcharts to guide technicians through the diagnostic process. Correcting differential binding requires meticulous attention to detail and adherence to the manual’s procedures to restore smooth and efficient power transfer.

Differential Leakage

Differential leakage, often signaled by oil spots, demands immediate attention, and a comprehensive differential adjustment PDF manual is crucial for effective repair. These manuals detail the differential’s sealing system, identifying potential leak sources like gaskets, seals, and vent plugs. They provide step-by-step instructions for disassembly, cleaning, and replacement of worn or damaged sealing components;

The manuals emphasize the importance of using the correct sealants and torque specifications to ensure a leak-free seal. They also cover procedures for inspecting the differential housing for cracks or damage that could contribute to leakage. Proper diagnosis, guided by the manual, prevents further damage and maintains optimal lubrication levels, safeguarding the differential’s internal components from premature wear and failure.

Advanced Differential Adjustment Techniques

PDF manuals unlock precision techniques like dial indicator use and gear marking pattern analysis, optimizing differential setup for racing or off-road applications.

Using Dial Indicators for Precision

Differential adjustment manuals (PDF) emphasize the critical role of dial indicators in achieving precise gear mesh. These tools allow technicians to measure backlash and pinion depth with exceptional accuracy, far exceeding estimations. PDF guides detail proper indicator mounting techniques, ensuring reliable readings. They illustrate how to interpret variations, pinpointing areas needing adjustment.

Understanding indicator resolution and proper lever arm usage, as explained in the manuals, is paramount. The PDFs often include diagrams showing optimal indicator placement for different differential types. Mastering dial indicator application, guided by these resources, minimizes noise, maximizes efficiency, and extends differential lifespan. Accurate measurements, facilitated by these manuals, are fundamental to a successful adjustment.

Understanding Gear Marking Patterns

Differential adjustment manuals (PDF) frequently detail the interpretation of gear marking patterns as a diagnostic tool. These patterns, visible after applying gear compound, reveal contact areas and stress points within the differential. PDF guides illustrate various patterns – optimal, excessive, or insufficient contact – and their implications for gear wear and performance.

Technicians use these manuals to correlate marking patterns with backlash and pinion depth settings. Understanding the patterns helps pinpoint specific adjustment needs. PDFs often include detailed charts and images showcasing different marking scenarios. Analyzing these patterns, as described in the manuals, allows for fine-tuning the differential, ensuring even load distribution and minimizing friction, ultimately extending component life and optimizing efficiency.

Setting Up Differential for Specific Applications (Racing, Off-Road)

Differential adjustment manuals (PDF) often dedicate sections to tailoring differential settings for specialized applications like racing or off-roading. These PDF guides explain how to modify backlash, preload, and ramp angles to optimize performance for specific demands. For racing, manuals detail tighter settings for quicker response and reduced wheel spin.

Conversely, off-road manuals recommend looser settings for increased articulation and durability. PDFs provide torque specifications and adjustment procedures unique to each application. Understanding these nuances, as outlined in the manuals, is crucial for maximizing traction and preventing component failure. Detailed charts and diagrams within the manuals illustrate the impact of each adjustment on vehicle handling.

Resources for Further Learning

PDF differential adjustment manuals are supplemented by online forums, technical articles, and manufacturer websites offering support and expanded knowledge.

Online Forums and Communities

Engaging with online forums and communities dedicated to automotive repair and specifically differentials provides invaluable support when working with a differential adjustment manual (PDF). These platforms allow users to share experiences, ask questions, and receive guidance from experienced mechanics and enthusiasts.

Many forums host dedicated threads for specific vehicle makes and models, ensuring relevant advice. Searching these forums using keywords from your PDF manual can quickly uncover solutions to common problems or clarify complex procedures.

Furthermore, community members often share tips, tricks, and even scanned pages from their own manuals, supplementing the information found in your downloaded PDF; Active participation fosters a collaborative learning environment, accelerating your understanding of differential adjustment.

Technical Articles and Videos

Complementing your differential adjustment manual (PDF) with technical articles and videos significantly enhances understanding. Numerous websites and YouTube channels offer detailed explanations of differential operation, adjustment procedures, and troubleshooting techniques. These resources often visually demonstrate complex steps, making them easier to follow than text-based instructions alone.

Search for articles specifically addressing your differential type (open, limited-slip, Torsen, electronic) to ensure relevance. Videos can showcase proper tool usage, gear marking patterns, and backlash measurement techniques.

Combining the comprehensive information within your PDF manual with these visual and explanatory resources creates a robust learning experience, improving your confidence and accuracy during the adjustment process.

Manufacturer Websites and Support

Directly accessing the vehicle or differential manufacturer’s website is a crucial step in obtaining the most accurate and up-to-date information. Many manufacturers offer downloadable differential adjustment manuals (PDF), technical service bulletins, and detailed diagrams specific to their products.

These resources often surpass generic manuals in precision and clarity, reflecting the latest engineering specifications and recommended procedures. Furthermore, manufacturers frequently provide dedicated support channels – phone, email, or online forums – where you can directly address specific questions or concerns.

Utilizing official manufacturer support ensures compatibility and minimizes the risk of errors during the adjustment process, safeguarding your differential’s performance and longevity.

PDF Manual Features and Functionality

PDF manuals offer searchable text, zoom capabilities, and annotation tools for easy navigation and understanding of complex differential adjustment procedures and diagrams.

Searchable Text and Indexing

A key benefit of differential adjustment manuals in PDF format is the inclusion of searchable text. This functionality allows technicians to quickly locate specific information within the document, saving valuable time during repairs. Instead of manually flipping through pages, users can simply type keywords – such as “pinion depth,” “backlash,” or a specific model number – to instantly find relevant sections.

Furthermore, well-structured PDFs often feature detailed indexing. This means the manual includes a comprehensive list of topics and subtopics, along with corresponding page numbers. This indexing system complements the search function, providing an alternative method for navigating the manual and accessing the information needed for accurate differential adjustments. Efficient searching and indexing are crucial for effective troubleshooting and repair work.

Zoom and Annotation Tools

Modern PDF readers offer powerful zoom capabilities, essential when examining detailed diagrams and schematics within a differential adjustment manual. Technicians can zoom in on specific areas to clarify intricate components and ensure accurate interpretation of instructions. Equally valuable are annotation tools, allowing users to add notes, highlights, and markings directly onto the PDF.

These annotations can be used to record measurements, flag important steps, or highlight potential issues. This interactive feature transforms the PDF from a static document into a dynamic workspace. Furthermore, annotation tools facilitate collaboration, enabling multiple technicians to share and review the manual with personalized notes, improving overall repair efficiency and accuracy.

Printable Format and Accessibility

A key benefit of differential adjustment manuals in PDF format is their printability. This allows technicians to have a physical copy readily available in the workshop, free from reliance on digital devices or internet connectivity. Accessibility features within PDF readers further enhance usability. These include text-to-speech functionality, aiding technicians with visual impairments, and adjustable font sizes for improved readability.

Moreover, PDFs are generally compatible across various operating systems and devices, ensuring broad accessibility. Properly formatted PDFs also maintain layout integrity when printed, preserving diagrams and tables for clear understanding. This combination of printability and accessibility makes PDF manuals a versatile and inclusive resource for automotive professionals.